Thermal Power: 120-10000KW

Design Pressure: 0.8Mpa

Maximum Working Temperature: 320℃

Fuel: Natural gas, LPG, LNG, CNG, Biogas, Urban Gas, Diesel Ooil, Heavy Oil, Oil and Gas.

WhatsApp: +86-17772877223 +86-15090452295

E-mail: info@yuji-boiler.com

Product Introduction

Gas Fired Thermal Oil Boiler uses PLC intelligent control, which can largely save manual operation, efficient and safe. Its large-diameter coil design can prevent the coil road from gelling. It realizes one boiler for multiple purposes, low operating noise, energy saving and environmental protection, long service life, high efficiency, safety and reliability. It uses an open-door design for easy maintenance and dirt removal. Also, we can provide you friendly price, on-time delivery and mature after-sales service.

Features

Gas Fired Thermal Oil Boiler has the advantages of high heat conduction temperature of 320℃ and low pressure of 0.8Mpa. It burns well inside and does not emit black smoke, creating a clean and healthy working environment for you. It adopts effective desulfurization and dust removal device, conducive to environmental protection and energy saving. Also, this boiler has compact structure, easy operation, and high safety degree.

Gas Fired Thermal Oil Boiler can be a good substitute for traditional boilers, because it is easy to operate, user-friendly setting, energy saving, and can avoid the problem of low energy utilization, complicated manual operation, poor safety, large exhaust gas emissions, etc. It realizes fully automatic intelligent control, easy maintenance, and can be left unattended. It has an advanced control system, which saves you investment costs while ensuring stable operation. It is widely used in chemical, pharmaceutical, food, feed, textile, building materials, hotels, heating and other industries.

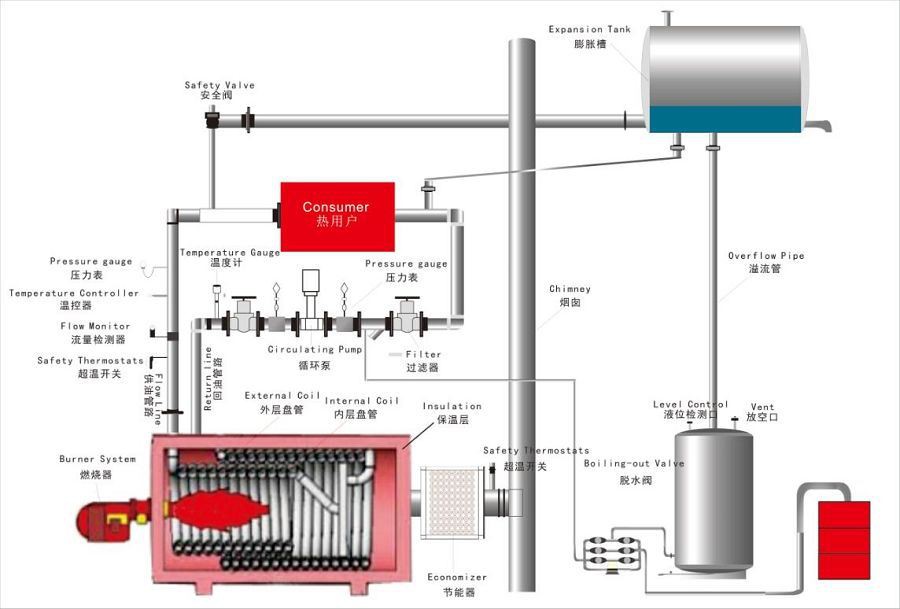

Product Chart

Product Parameter

Model: YY(Q)W Series

Thermal Power: 120-10000KW

Design Pressure: 0.8Mpa

Maximum Working Temperature: 320℃

Fuel: Natural gas, LPG, LNG, CNG, Biogas, Urban Gas, Diesel Ooil, Heavy Oil, Oil and Gas.

|

Model |

Rated power (kw) |

Rated pressure (MPa) |

Thermal efficiency (%) |

Medium outlet temperature(℃) |

Medium return temperature(℃) |

Dimension L×W×H (m) |

Weight(t) |

|

YY(Q)W-700Y(Q) |

700 |

0.8/1.0 |

≥93 |

320 |

280 |

3.2×2×2.1 |

4.9 |

|

YY(Q)W-1000Y(Q) |

1000 |

0.8/1.0 |

≥93 |

320 |

280 |

3.5×2×2.1 |

5.2 |

|

YY(Q)W-1400Y(Q) |

1400 |

0.8/1.0 |

≥93 |

320 |

280 |

4.5×2×2.3 |

6.2 |

|

YY(Q)W-2100Y(Q) |

2100 |

0.8/1.0 |

≥93 |

320 |

280 |

5.4×2.4×2.6 |

10 |

|

YY(Q)W-3000Y(Q) |

3000 |

0.8/1.0 |

≥93 |

320 |

280 |

6×2.5×2.8 |

13 |

|

YY(Q)W-4200Y(Q) |

4200 |

0.8/1.0 |

≥93 |

320 |

280 |

7.1×3×3.2 |

18 |

|

YY(Q)W-6000Y(Q) |

6000 |

0.8/1.0 |

≥93 |

320 |

280 |

8.1×3.2×3.5 |

26 |

|

YY(Q)W-7000Y(Q) |

7000 |

0.8/1.0 |

≥93 |

320 |

280 |

9×3.4×3.7 |

30 |

Performance Advantages

1. High efficiency, low cost

(1) Combustion equipment is customized according to different fuels, all kinds of fuels can be fully burned, high efficiency, low consumption, and environmental protection.

(2) Energy saver installed at the end of the boiler, make full use of thermal energy and improve thermal efficiency.

(3) High temperature resistant heat insulation material, prevent heat loss.

2. High-security operation,ensure no safety hazards

(1) Set a number of safety protection devices, safety valves, pressure controllers, pressure transmitters, pressure gauges, oil temperature control, nitrogen fire extinguishing, etc.

3. Quick assembly, simple installation

Boiler and auxiliary machine are assembled structure, convenient transportation, simple installation, short cycle

1. Material re-inspection: Ensure materials meet standards

2. Pretreatment of materials: Surface derusting and non-destructive testing, plate calibration

3. Cutting process: CNC cutting machine for lofting and processing

1. Forming: The drum is integrally formed. Using corrugated furnace process

2. Welding: Automatic welding, beautiful appearance, low repair rate and high efficiency

3. Correction: The welded drum is rounded to ensure the roundness of the drum

1. Non-destructive testing: Non-destructive testing, mechanical performance testing

2. Hydrostatic test: Check its strength and tightness

3. Trial burning: Safety and Stability Tests

1. Paint: First remove rust, then apply antirust primer, and finally apply high temperature resistant metal paint

2. Packaging: Packaging with special equipment

3. Transportation: Ensure safe and fast transportation of boilers and auxiliary equipment

Please let us know your required steam capacity, working pressure or steam temperature, fuel type. Then our aftersales-engineer will send you the detailed and exact offer.

Usually our company have new stocks, we can manage the shipping within 5-10 days. But you please contact us salesman to confirm in advance.

Yes, our company will provide the drawings and operation manual. Also you can contact us for help, then our engineer can give you the technical supports online.

1. Structure of vertical boiler is compact, occupy a limited area.

2. Convenient on installation and removal.

3. Low cost and investment on capital construction. Steam exhausted fast and sufficient.

4. The combustion space of horizontal is big, fuel can be burned completed.

5. The thermal efficiency is higher than the vertical boiler.

6. Horizontal type: less thermal loss, stronger output, and higher steam quality.

Our boilers have one year warranty period or depending on your requirements.

1. We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model.

2. Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

1. Strength calculation report with applied materials information.

2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod.

3. 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler.

4. Hydrostatic test: ensure the standard working pressure and safety.

5. Third-party inspection report:By Henan Boiler Inspection Institute.

6.Passed ISO:9001 ,ISO14001,OHASA18001 and CE certificate.

1. We have 20, 000 m² factory area, More than 200 employees. We can efficiently complete your delivery project.

2. Our boiler vessel export to more than 100+ countries, Well Received by Customers.

3. Our boiler vessel have passed the ISO 9001 system certification, EU CE and other international certifications, worthy of your trust.

4. Through the quotation consultation form you submitted, we will give you a quotation and construction solution in the shortest time.

Quote

Business: info@yuji-boiler.com

Technology: clinton@yuji-boiler.com

After sales: admin@yuji-boiler.com

Phone

+86-17772877223

+86-15090452295

The price will be sent soon via email.